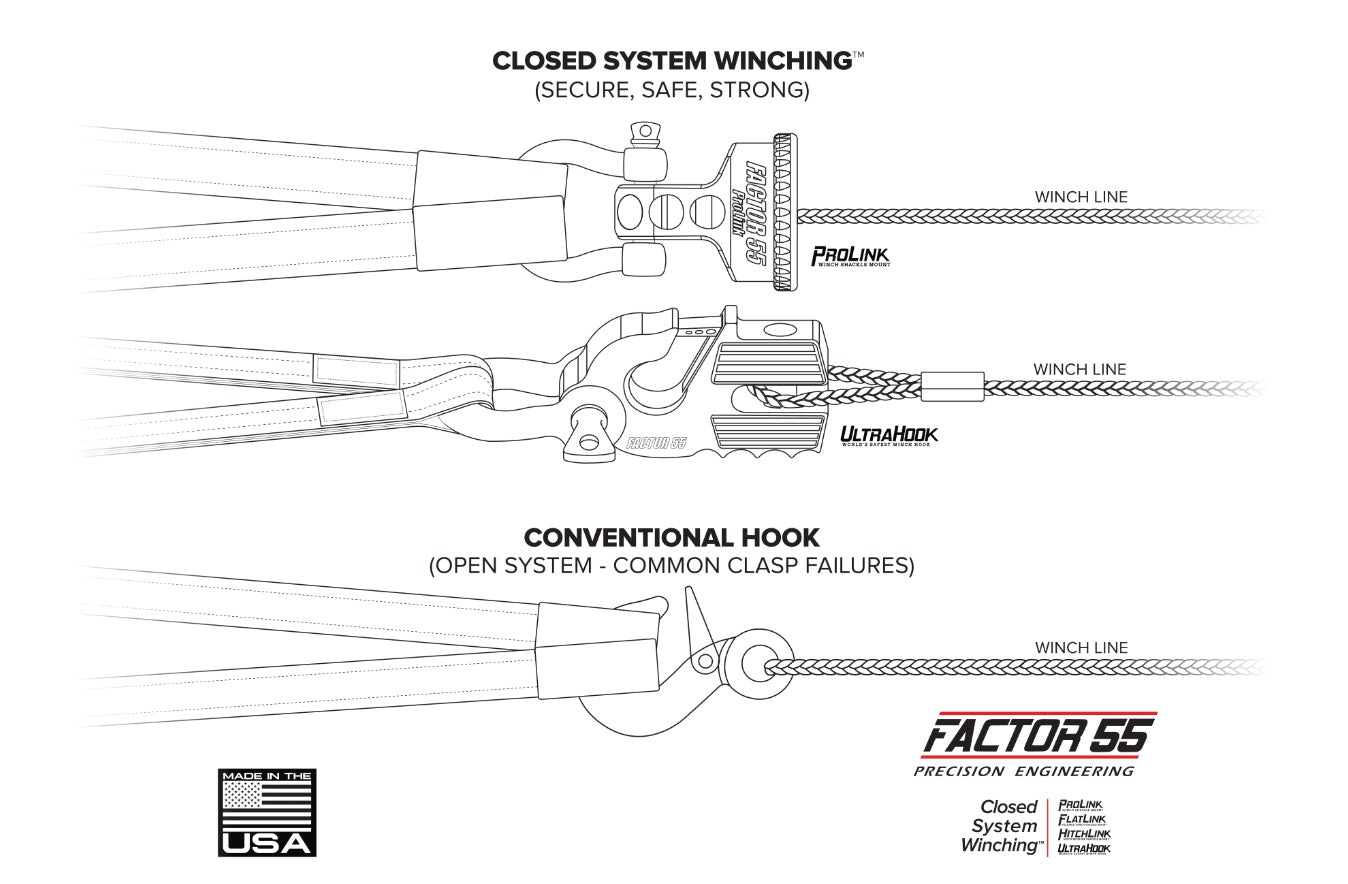

CLOSED SYSTEM WINCHING™ is a winching technique using rigging comprised entirely of closed link hardware. The non-closable opening of common winch hooks prevent hooks from qualifying as secure closed links. Poorly constructed sheet metal safety latches of hooks do not qualify as a secure means to contain loads and are prone to failure, especially during momentary slack conditions where winch loads often shift and apply high forces to these weak non-structural latches. Hooks often come loose during vehicle recovery operations due to hook safety latch failures.

The elimination of the winch hook and the subsequent substitution to a Factor 55 ProLink, FlatLink, or UltraHook shackle mount and commonly found screw pin shackles/D-Rings does qualify as CLOSED SYSTEM winch tackle. Once a shackle screw pin is installed, the common screw pin shackle becomes a continuous closed link that securely contains the winch load until the pin is unscrewed and removed.

The ProLink, FlatLink, and UltraHook patented winch shackle mount products by Factor 55 address this winch safety issue by providing a secure screw pin shackle mounting interface to all steel winch cables and synthetic winch ropes. The Factor 55 unique double shear pin design provides a simple trouble free method of attaching existing cable and rope eyes to the ProLink, FlatLink, and UltraHook products. Installation requires only minutes. Once installed, the ProLink/Flatlink/UltraHook products provide a precision mounting hole for screw pin shackles and also provide a large rubber protected flat surface to cushion against all fairlead mounting surfaces.

Whether the winch line is in tension or a dangerous momentary slack condition, CLOSED SYSTEM WINCHING™ keeps all winch tackle secure and is by far the safest method of operating your vehicle recovery winch.